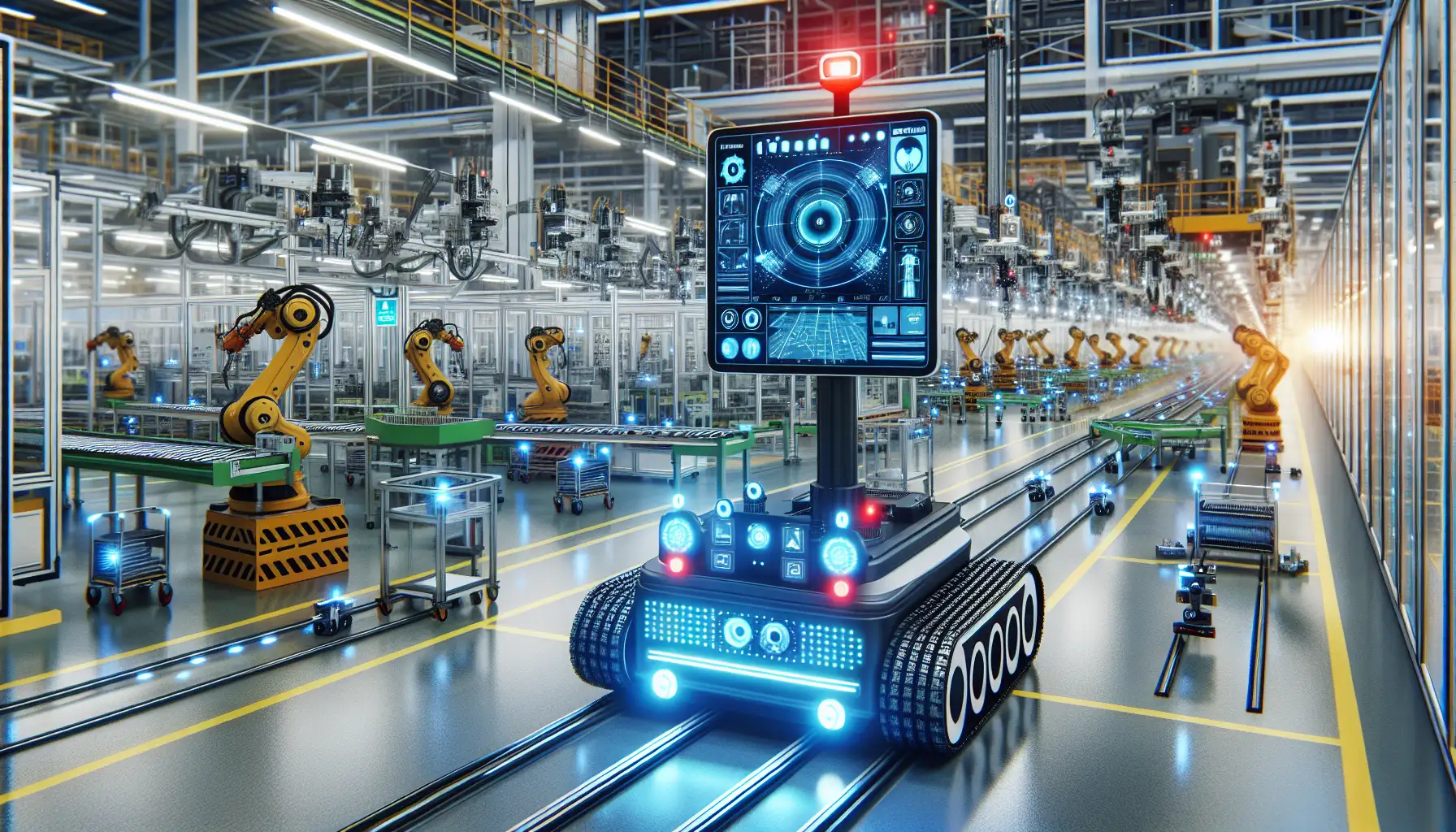

Discover the capabilities and applications of the Topband AGV-V2440A, a cutting-edge automated guided vehicle designed for modern industrial operations. This comprehensive guide explores its features, benefits, and impact on warehouse automation.

Introduction to the Topband AGV-V2440A

The Topband AGV-V2440A represents a significant advancement in automated material handling technology. This sophisticated automated guided vehicle combines precision engineering with intelligent navigation systems to streamline warehouse operations and enhance productivity. As industries continue to embrace automation, the Topband AGV-V2440A stands out for its versatility, reliability, and advanced features that address the evolving needs of modern manufacturing and distribution facilities.

Core Features and Capabilities

The fundamental design of the Topband AGV-V2440A incorporates several innovative features that set it apart in the automated guided vehicle market. Its robust construction ensures durability in demanding industrial environments, while its advanced control systems enable precise navigation and handling capabilities.

Key Features:

- Advanced navigation system

- Precision control mechanisms

- Robust safety features

- Intelligent obstacle detection

- Flexible payload capacity

- Extended operational runtime

Technical Specifications

The Topband AGV-V2440A boasts impressive technical specifications that demonstrate its capabilities as a premier automated guided vehicle solution.

Performance Parameters

| Specification | Value |

|---|---|

| Maximum Speed | 1.5 m/s |

| Payload Capacity | 2400 kg |

| Operating Time | 12-14 hours |

| Charging Time | 2-3 hours |

| Navigation Accuracy | ±10mm |

| Turning Radius | 1.8m |

Dimensional Specifications

The physical dimensions of the Topband AGV-V2440A are optimized for efficient operation in various industrial settings:

- Length: 1.8 meters

- Width: 1.2 meters

- Height: 0.45 meters

- Ground Clearance: 35mm

Navigation and Control Systems

The Topband AGV-V2440A employs sophisticated navigation and control systems that ensure precise movement and positioning throughout facilities.

Navigation Technologies

The vehicle utilizes multiple navigation methods:

- Laser Navigation

- Magnetic Tape Guidance

- Natural Navigation

- QR Code Positioning

Control Architecture

The control system of the Topband AGV-V2440A features:

- Centralized fleet management

- Real-time position monitoring

- Dynamic path planning

- Collision avoidance algorithms

Safety Features and Compliance

Safety is paramount in the design of the Topband AGV-V2440A, with multiple systems working together to ensure secure operation.

Safety Systems

The comprehensive safety features include:

- Emergency stop buttons

- Multiple safety sensors

- Visual and audible warnings

- Automatic obstacle detection

- Speed zone management

- Personnel detection systems

Applications and Use Cases

The Topband AGV-V2440A serves various industrial applications across different sectors.

Manufacturing Applications

In manufacturing environments, the Topband AGV-V2440A excels at:

- Production line material delivery

- Work-in-progress transport

- Finished goods handling

- Tool and equipment movement

- Component distribution

Warehouse Operations

Within warehouse settings, common applications include:

- Order fulfillment support

- Inventory transport

- Cross-docking operations

- Returns processing

- Sorting and distribution

Integration and Implementation

Successfully implementing the Topband AGV-V2440A requires careful planning and integration with existing systems.

System Requirements

Key considerations for implementation include:

- Facility Layout Assessment

- Network Infrastructure

- Charging Station Placement

- Traffic Management Systems

- Emergency Response Protocols

Maintenance and Support

Regular maintenance ensures optimal performance and longevity of the Topband AGV-V2440A.

Preventive Maintenance Schedule

Standard maintenance requirements include:

- Daily visual inspections

- Weekly system checks

- Monthly performance analysis

- Quarterly comprehensive service

- Annual certification review

Return on Investment Analysis

Understanding the financial benefits of implementing the Topband AGV-V2440A is crucial for business planning.

Cost Considerations

Important factors in ROI calculation:

- Initial investment

- Installation costs

- Operating expenses

- Maintenance requirements

- Labor savings

- Productivity gains

Future Developments and Updates

The Topband AGV-V2440A continues to evolve with technological advancements and industry needs.

Upcoming Features

Anticipated developments include:

- Enhanced AI capabilities

- Improved battery technology

- Advanced sensor systems

- Extended connectivity options

- Expanded software features

Key Takeaways

- Advanced Navigation: The Topband AGV-V2440A utilizes multiple navigation technologies for precise movement

- Safety Focus: Comprehensive safety features ensure secure operation

- Versatile Applications: Suitable for various industrial environments

- Strong ROI Potential: Significant cost savings through automation

- Future-Ready: Continuous development and feature updates

Frequently Asked Questions

What is the maximum payload capacity of the Topband AGV-V2440A?

The Topband AGV-V2440A can safely handle loads up to 2400 kg.

How long can the Topband AGV-V2440A operate between charges?

The system typically operates for 12-14 hours on a single charge.

What navigation systems does the Topband AGV-V2440A use?

It employs multiple navigation methods including laser, magnetic tape, natural navigation, and QR code positioning.

Is the Topband AGV-V2440A suitable for existing warehouse operations?

Yes, it's designed to integrate seamlessly with existing warehouse management systems and infrastructure.

Conclusion

The Topband AGV-V2440A represents a significant advancement in automated guided vehicle technology, offering a robust solution for modern industrial automation needs. Its combination of advanced features, safety systems, and versatile applications makes it a valuable investment for facilities looking to enhance their material handling capabilities.